在最近发表在《MethodsX》杂志上的一项研究中,来自宝岛台湾的研究人员开发了一种新方法,通过对从鱼鳞废料中提取的胶原蛋白肽进行酯化聚合,合成天然柔软的彩色聚酯。

In a recent study published in the journal MethodsX, researchers from Taiwan developed a novel method to synthesize naturally soft and colored polyester through esterification polymerization of collagen peptides extracted from fish scale waste.

图片版权(Image Credit):摄图网_503413328_鱼鳞鲑鱼宏图(企业商用)

研究:一种从鱼鳞废料中提取胶原蛋白改性聚酯的工艺方法(翻译)Study: A Method for the Process of Collagen Modified Polyester from Fish Scales Waste.

胶原蛋白肽形成了含有甘氨酸、脯氨酸和羟脯氨酸的三螺旋结构,从而增强了亲水性、抗静电性、延展性、耐久性、强度、抗皱性和收缩性,与传统的聚对苯二甲酸乙二醇酯(PET)纤维相当。此外,其香槟色的天然颜色和柔软的质地使其适合于无染料的亲肤有价值的纺织面料。

The collagen peptide formed a triple helix structure containing glycine, proline, and hydroxyproline, which resulted in enhanced hydrophilicity, antistatic properties, ductility, durability, strength, and resistance to wrinkle and shrink, which are comparable to that of traditional polyethylene terephthalate (PET) fibers. Moreover, its champaign like natural color and soft texture makes it suitable for dye-less skin-friendly valuable textile fabri

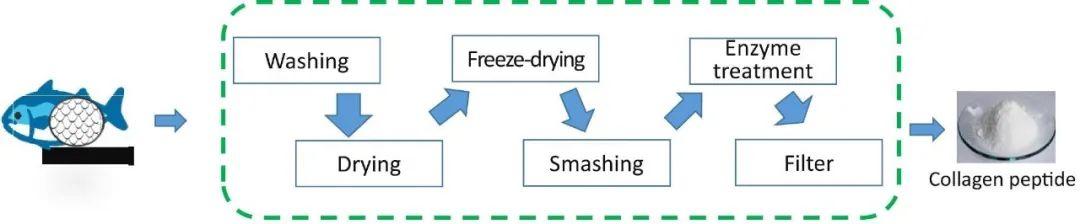

图示:鱼鳞提取胶原蛋白肽过程。图片来源:《MethodsX》杂志Hou, E等人The process of Collagen peptide from fish scales. Image Credit: Hou, E et al., MethodsX

背景说明

Background

最常用的热塑性聚酯是PET([C10H8O4]n),它是产量第四大的合成聚合物,占世界聚合物总产量的18%。它由85%以上的乙二醇和对苯二甲酸组成。以PET为基础的纺织品重量轻、耐用、无褶皱。然而,它的气密性、较硬的质地和较差的吸湿性使它在纯粹的形式下成为不舒服的纺织材料。因此,聚酯大多与其他织物混纺或交织在纺织产品中。

The most commonly used thermoplastic polyester is PET ([C10H8O4]n), which is the fourth most produced synthetic polymer and contributes to 18% of the total polymer production of the world. It is composed of more than 85%, ethylene glycol, and terephthalic acid. PET-based textiles are lightweight, durable, and wrinkle-free. However, its airtightness, harder texture, and poor hygroscopicity make it an uncomfortable textile material in pure form. Thus, polyesters are mostly blended with other fabrics or interwoven in textile products.

同时,胶原蛋白肽是人类必需的蛋白质补充剂,它只能从动物身上获得,而不能从植物身上获得。水生动物,如鱼类,在其皮肤和鳞片中含有大量的胶原蛋白肽。

Meanwhile, collagen peptides are essential protein supplements for human beings, which can only be obtained from animals but cannot be obtained from plants. Aquatic animals such as fish have a high content of collagen peptides in their skin and scales.

许多沿海地区有大量的渔业中心,产生水生废料。此外,从鱼鳞中提取的胶原蛋白不含脂肪、朊病毒和抗生素,与从陆地动物中提取的胶原蛋白不同。含有甘氨酸、脯氨酸和羟脯氨酸的三α链的胶原蛋白可以被组装成复杂的分层纤维,用于纺织材料中。

Many coastal regions have a large number of fishing hubs that produce aquatic waste materials. Moreover, collagen extracted from fish scales are fat-, prion-, and antibiotic-free contrary to collagens extracted from land animals. Three α-chains of collagen consisting of glycine, proline, and hydroxyproline can be assembled into complex hierarchical fibers for use in textile materials.

从鱼鳞中提取胶原蛋白肽

Extraction of Collagen Peptides from Fish Scales

首先,本研究的研究人员从鱼鳞粉末中提取胶原蛋白肽。用去离子水彻底清洗鱼鳞,并在真空条件下进行冻干。然后鱼鳞研磨成细粉状,用酶处理。通过离心过滤将水解液从固体物基质中分离出来,并进一步干燥以得粉末状的胶原蛋白肽。

Firstly, researchers in this study extracted the collagen peptide from the fish scales in powder form. The fish scales were thoroughly washed with deionized water and dried and cooled under vacuum conditions. Later, they were crushed and ground to fine powder form, followed by treatment with enzymes. Finally, the hydrolyzed liquid was segregated from the solid mineral base via centrifugal filtration and further dried to obtain the collagen peptide in powder form.

图片来源:《MethodsX》杂志Hou, E等人Image Credit: Hou, E et al., MethodsX

Image Credit: Hou, E et al., MethodsX

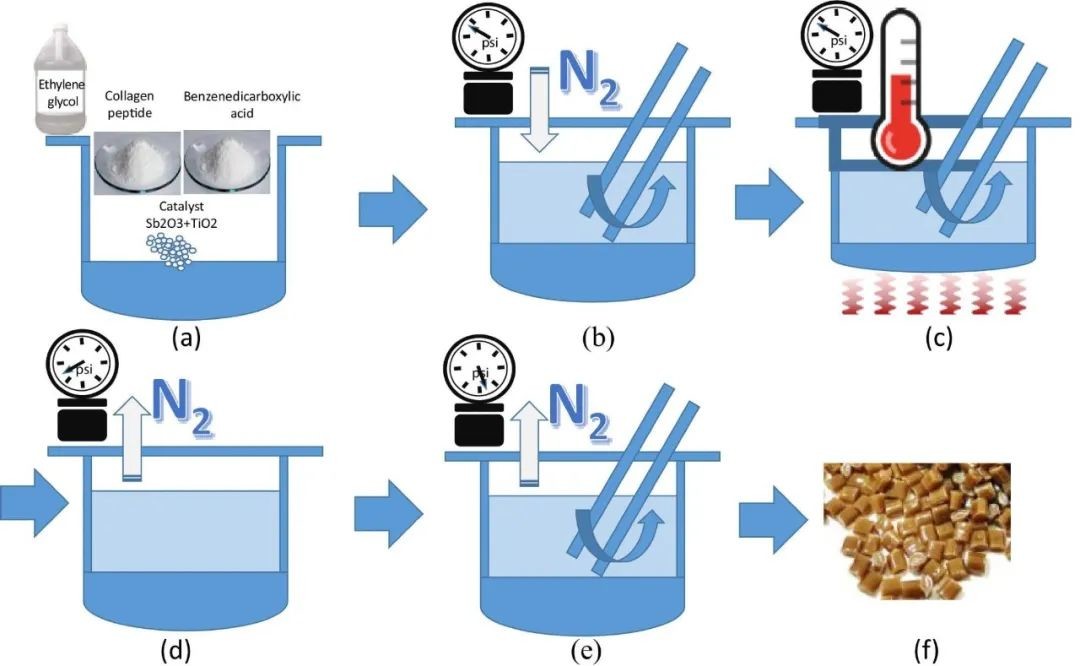

超分子聚合的阶段。(a)混合原料和催化剂,(b)向容器中引入氮气并搅拌混合物,(c)加热混合物以执行210℃至270℃的酯化反应,(d)将容器中的压力降至20托(Torr),进行缩聚反应,(e)将容器中的压力降至3托,形成共聚酯材料,(f)生产的仿生聚酯颗粒。压力的数值不限于此,可以根据需要改变。

The stages of supramolecular polymerization. (a) mixing of raw materials and catalysts, (b) Introducing nitrogen into the container and stirring the mixture, (c) Heating the mixture for executing an esterification reaction from 210°C to 270°C, (d) Decreasing the pressure to 20 torr in the container for a polycondensation reaction, (e) Decreasing the pressure to 3 torr in the container and forming copolyester material and (f) the produced bionic polyester pellets. The values of pressure are not limited thereto and can be changed in accordance with the needs.

胶原蛋白肽的酯化为聚酯纤维

Esterification of Collagen Peptide into Polyester

从鱼鳞中提取的胶原蛋白肽粉末与苯二甲酸、乙二醇和几种催化剂混合。苯二甲酸可以是纯对苯二甲酸(TPA)或纯间苯二甲酸(IPA),或TPA和IPA的混合物。催化剂是氧化锑(Sb2O3)和氧化钛(TiO2)的混合物,百万分之一(ppm)的浓度比在(160-360):(0-60)的范围内。

The collagen peptide powder extracted from the fish scales was mixed with benzene dicarboxylic acid, ethylene glycol, and several catalysts. Benzene dicarboxylic acid can be pure terephthalic acid (TPA) or pure iso-phthalic acid (IPA), or a mixture of TPA and IPA. The catalyst was a mixture of antimony oxide (Sb2O3) and titanium oxide (TiO2) with a parts per million (ppm) concentration ratio in a range of (160-360):(0-60).

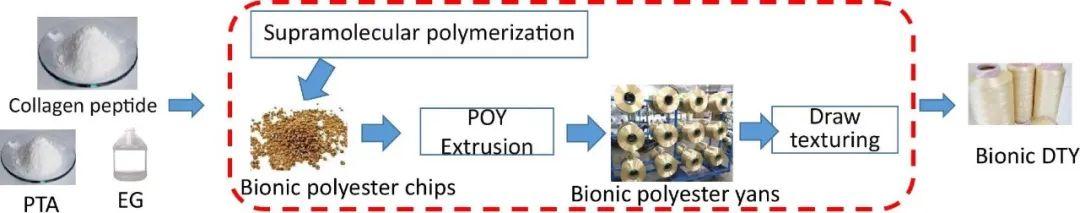

随后,氮气环境下,该混合物在210-270℃的温度和20torr的压力下融化成糖浆状溶液,并倒入喷丝板,溶液在离心压力下穿过喷丝板的小孔,形成局部方向一致的纱线(POYs)。之后,胶原蛋白改性的POY被拉伸形成拉伸纹理纱线(DTYs)。最后,生产出来的仿生DIY材料被用于制造纺织产品。Subsequently, the mixture was melted at 210-270 ℃ temperature and 20 torr pressure into a syrup-like solution under a nitrogen atmosphere and poured into a spinneret. The solution was centrifugally forced through the tiny holes of the spinneret to form partially oriented yarns (POYs). After that, the collagen-modified POY was drawn to form drawn textured yarns (DTYs). Finally, the produced bionic DIY was used for the fabrication of textile products.

胶原蛋白改性聚酯材料生产过程。图片来源:《MethodsX》杂志Hou, E等人

The process of producing collagen modified polyester materials. Image Credit: Hou, E et al., MethodsX

结论

Conclusions

总而言之,本研究的研究人员用从鱼鳞中提取的胶原蛋白肽制作了纺织面料。与市面上的PET纺织品相比,所制备的织物具有类似于香槟的自然颜色和柔软的质地。此外,三螺旋α链的层次结构具有更好的强度、亲水性和同等的无皱面料,使其更具吸引力。生物废料的再生使用也为其验收成品增加了溢价,同时也为循环经济做出了贡献。To summarize, the researchers of this study fabricated textile fabric from collagen peptides extracted from the fish scales. The prepared fabric had a natural champaign-like color and soft texture compared to the commercially available PET textiles. Moreover, the triple helix α-chain hierarchical structure with improved strength, hydrophilicity, and the same wrinkle-free behavior makes it more appealing. Bio-waste recycling also adds a premium value to the finished product and, at the same time, contributes to the circular economy.

青岛融智汇作为一家以海洋生物医用材料高新技术开发为主的科技型企业,已开发多个基于鱼鳞胶应用的产品,融智汇通过提供科学有效高品质的功能性鱼鳞胶帮助解决中国大众市场的泛健康问题。融智汇旗下产品矩阵涵盖:

一、海洋生物矿化硅止血系列

- 融智汇与各军地单位联合开发基于硅藻为原料的超快速DBs基止血产品。该项发明拥有独立的知识产权,利用“藻种+海水+阳光”的生物制造方法,研发的DBs止血产品可以用于战伤救治,推动军队战救止血的升级换代,具有极为重要的国防意义;同时也在地震、火灾、车祸等灾害伤员的临床救治中发挥重要作用。国内外尚无除项目组外的报道与专利,产出成果将填补我国在高端海洋生物医用材料领域的空白。

- 本项目连续获得国家自然科学基金重点项目(U1706212)和青年项目(81801846)的支持。相关制备技术申请国家发明专利4项,授权2项(ZL201610494583.7、ZL201610732723.X)。

二、鱼鳞胶系列

- 用于功能性食品且富含深海提取鱼鳞胶原蛋白的鱼鳞胶口服液、骨质素,能够有效增强人体免疫力;

- 用于小创口、擦伤、切割伤等浅表性创面及周围皮肤护理的鱼鳞胶伤口护理软膏;

- 用于人体物理退热、体表面特定部位降温的医用冷敷贴;

- 用于烧伤、溃疡等创面愈创的冷敷凝胶;

- 用于皮炎、湿疹等皮肤止痒消肿的喷剂敷料;

- 海洋生物化妆品及保健品等系列产品

青岛融智汇鱼鳞胶产品,传承古法鱼鳞胶制法及现代医学科研成果。每一滴鱼鳞胶,都是活的传承。海洋力量,自然肤康;选得对,更放心:持证"上岗”国家认证 + 医药平台背书放心采购。

✅家族身份

-中韩院士共同背书

-中国海洋大学技术加持

✅科研力量

-韩国高丽大学朴贤镇(Hyun Jin Park)院士

-俞梦孙院士:中国工程院院士、航空医学与生物医学工程专家、我国航空生物医学工程的创始人和奠基人

-首席科学家:陈西广教授:中国海洋大学海洋生物材料专家(泰山学者)

-科研团队构成:985/211高校教授、副教授、博士后、博士以及硕士等高学历人才

✅市场背书

-合作单位涵盖:中国海洋大学、301解放军总医院海南医院、烟台大学、海南聚能科技创新研究院、青岛海慈医疗集团、青岛大学附属医院、福建第二人民医院、医联平台、药师帮等

更多鱼鳞胶产品及应用资讯,请关注青岛融智汇官方账号,随时解密海洋精华。

参考来源:

References:

1)Hou, E., Huang, C., Lee, Y., Han, Y., Chu, H., A Method for the Process of Collagen Modified Polyester from Fish Scales Waste, MethodsX, 2022, 101636, ISSN 2215-0161, https://www.sciencedirect.com/science/article/pii/S2215016122000218